Product category產(chǎn)品類別

TECH. SUPPORT

- General Manager :

- Mr.SHIAN.XIE

- WhatsApp/Wechat :

- 13587438287

- Email :

- shianxie@126.com

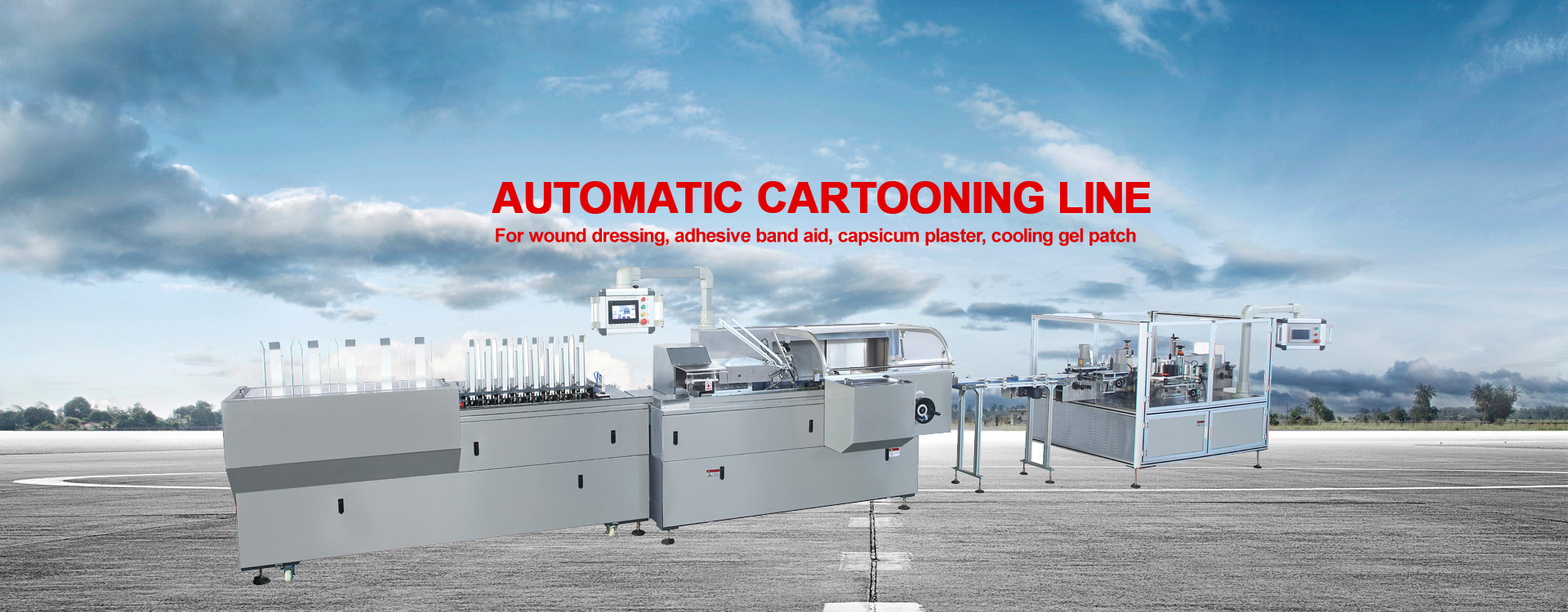

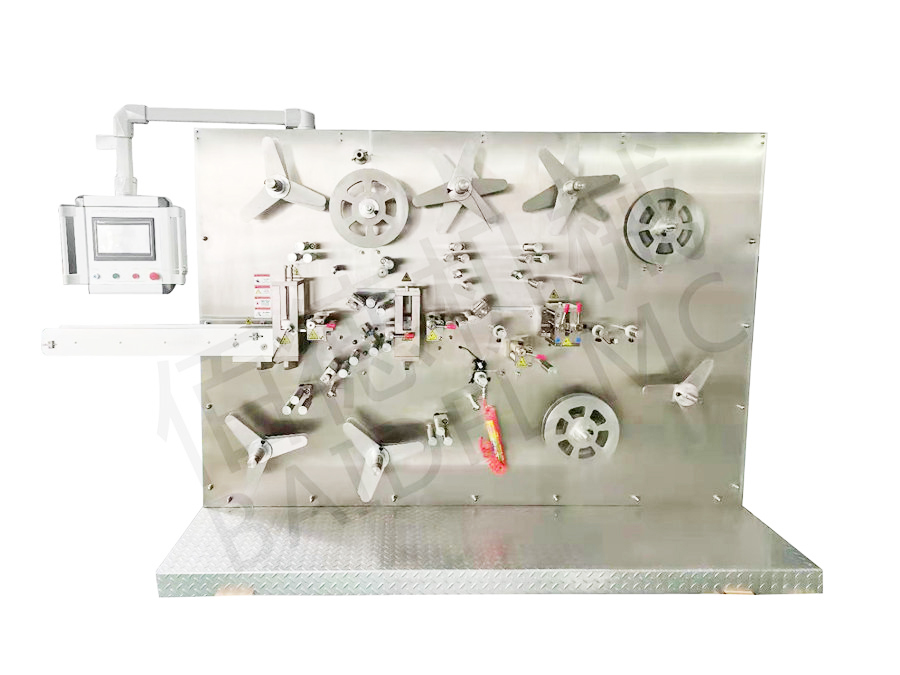

· Name of machine: fully automatic wound dressings manufacturing and packing line

· This machine can manufacture wound dressings based on nonwoven and transparent PU wound dressing

· Normal PLC replaced by advanced motion controller system

· Each station adopts servo motor controlling, includes: basic materials peeling mechanic,

pad traction mechanic, pad rotary die cutting mechanic, plaster traction mechanic,

plaster rotary cutting mechanic, hot sealing, package traction mechanic,

package rotary die cutting mechanic

· Three sections of materials unwind mechanic for customer (three options):

manual tension controller, constant tension controller, full servo controlling

· Hot sealing type: mold pressing

Advantage1: high quality hot sealing

Advantage2: hot sealing plates are freely to change for different size

· Maximum size: 120x350mm

· It’s possible to change the rotary die for different sizes in the effective width

· According to customer special requirements, up and down packing mechanic with eye marks tracking

· According to customer special requirements, up and down packing mechanic with auto-rectifying

mechanic

· Production speed up to 120-150pouches/min (based on 100x100mm)

· Total power: 12Kw

· Machine size (length x width x height): 3500x1150x2200mm

· Machine approx. weight: 2500Kg

· This machine can manufacture wound dressings based on nonwoven and transparent PU wound dressing

· Normal PLC replaced by advanced motion controller system

· Each station adopts servo motor controlling, includes: basic materials peeling mechanic,

pad traction mechanic, pad rotary die cutting mechanic, plaster traction mechanic,

plaster rotary cutting mechanic, hot sealing, package traction mechanic,

package rotary die cutting mechanic

· Three sections of materials unwind mechanic for customer (three options):

manual tension controller, constant tension controller, full servo controlling

· Hot sealing type: mold pressing

Advantage1: high quality hot sealing

Advantage2: hot sealing plates are freely to change for different size

· Maximum size: 120x350mm

· It’s possible to change the rotary die for different sizes in the effective width

· According to customer special requirements, up and down packing mechanic with eye marks tracking

· According to customer special requirements, up and down packing mechanic with auto-rectifying

mechanic

· Production speed up to 120-150pouches/min (based on 100x100mm)

· Total power: 12Kw

· Machine size (length x width x height): 3500x1150x2200mm

· Machine approx. weight: 2500Kg

Previous:wound dressing machine

Next:抱歉暫無(wú)數(shù)據(jù)